East India Automation & Control

Kolkata, India ![]() GST No.19AJAPG3138J1ZB

GST No.19AJAPG3138J1ZB

Call us now

07971191428CNC Retrofitting Installation Services

About this product

Comprehensive Control System Compatibility

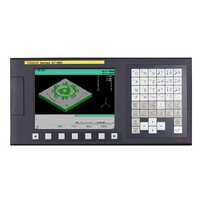

We retrofit CNC machines with advanced control systems from top manufacturers such as Fanuc, Siemens, and Mitsubishi, ensuring tailored solutions for your equipment. Our service accommodates a variety of machine types across numerous industrial applications, enhancing performance and reliability regardless of the manufacturer or model.

Efficient Installation and Support

Installation is completed swiftly-typically within 1 to 2 weeks-minimizing equipment downtime. Our technicians provide onsite support anywhere in India, along with thorough operator training to ensure seamless transition and quick adaptation. We also offer 12 months of warranty and dependable after-sales maintenance for continued operational excellence.

FAQ's of CNC Retrofitting Installation Services:

Q: How do you ensure compatibility with my existing CNC control system?

A: Our team assesses your machine's specifications and selects compatible control systems such as Fanuc, Siemens, or Mitsubishi. We tailor the retrofit to match your equipment's requirements, guaranteeing smooth integration and optimal performance.Q: What is the typical installation time for CNC retrofitting services?

A: Installation of CNC retrofitting, including control system upgrades, typically takes 1 to 2 weeks. This timeframe includes complete set-up and verification to minimize disruption to your operations.Q: Where are your CNC retrofitting installation services available?

A: We provide CNC retrofitting installation and support services across all regions of India, ensuring industries nationwide have access to top-tier upgrades and support.Q: What is included in your after-sales maintenance service?

A: After the retrofit, we offer ongoing maintenance services, which include periodic inspections, troubleshooting, and repairs to maximize machine uptime and efficiency throughout the service warranty period and beyond.Q: How is operator training conducted for the new CNC control systems?

A: Operator training is delivered onsite by our experts after retrofit installation. We provide hands-on learning to ensure operators are confident and fully understand the new system's functionalities and safety procedures.Q: What are the power requirements for the retrofitted CNC machines?

A: Retrofitted machines operate on standard industrial power supply-either 220V or 415V-suitable for most factory environments.Q: What are the key benefits of CNC retrofitting for industrial applications?

A: CNC retrofitting significantly boosts productivity, extends machine lifespan, and adds modern functionalities. It reduces the need for costly new equipment investments while increasing overall efficiency and reliability.Industrial CNC Retrofitting Services

50000 INR/Number

Minimum Order Quantity : 1 Number

About this product

Comprehensive Retrofitting Solutions

We specialize in upgrading CNC machines across mechanical, electrical, and control system components. Our certified engineers ensure each retrofit aligns precisely with client needs, enhancing reliability and functionality for manufacturing operations.

Nationwide Coverage and Support

Our services are available throughout India, offering both on-site and remote assistance options. Whether your facility is centrally located or in a remote region, our team is equipped to provide prompt, effective support for minimal downtime.

Customization and Maintenance

Every retrofit project is unique. We offer fully customized solutions to suit specific applications and machine models. Additionally, clients may opt for annual maintenance contracts, ensuring long-term performance and peace of mind.

FAQ's of Industrial CNC Retrofitting Services:

Q: How does the CNC retrofitting process work?

A: Our retrofitting process begins with a thorough assessment of your current CNC machine. We then design a custom plan to upgrade mechanical, electrical, and control system components, ensuring optimal compatibility. Certified engineers carry out installation and testing-either on-site or under remote guidance.Q: What type of CNC machines can you retrofit, and which brands are compatible?

A: We retrofit a variety of industrial CNC machines from leading brands such as Fanuc, Siemens, Mitsubishi, and more. Each project is tailored to your specific equipment for maximum performance and reliability.Q: When should an industrial CNC machine be retrofitted?

A: Retrofitting is ideal when machines show signs of outdated components, recurrent breakdowns, or when enhanced automation and improved accuracy are desired. It extends machine lifespan without the need for complete replacement.Q: Where do you provide your CNC retrofitting services?

A: We serve manufacturing industries across all regions of India, ensuring consistent support through on-site visits or remote assistance, based on your project's needs and geographic location.Q: What benefits does a CNC retrofit offer over buying new equipment?

A: Retrofitting boosts performance, accuracy, and reliability at a significantly lower cost compared to purchasing new machinery. It also reduces operational disruptions and is often customizable to exact specifications.Q: Can the service be customized to my specific requirements?

A: Yes, our services are fully customizable to accommodate your machine type, brand, and operational needs. Our certified and experienced engineers work closely with you to deliver the ideal solution.Q: What kind of support and maintenance options are available after retrofitting?

A: We offer continuous support through both on-site and remote channels. Annual maintenance contracts are optional, ensuring your retrofitted machine operates smoothly and efficiently over time.Industrial CNC Machine Retro Fitment Services

50000 INR/Number

Minimum Order Quantity : 1 Number

About this product

We are involved in offering perfect CNC Retro Fitment Services to our valued clients. these services are specially utilized to strengthen and rehabilitate weak structure, which further ensure maximum durability and high tensile strength of the structure. Our services are rendered by experienced team members, using best quality components and following international industrial standards. We provide these services at budget friendly rates.

Features:

- Reliability

- Timeliness

- Flexibility

Comprehensive CNC Machine Upgrade Solutions

We deliver end-to-end retrofitting for industrial CNC machines, focusing on mechanical and electrical upgrades to maximize machine performance and productivity. From axes drive replacements to sophisticated panel and wiring enhancements, our retro-fitment services extend the life and capability of your machines across a range of supported models.

Expertise in Leading Control Systems

Our team excels in upgrading CNC machines equipped with Siemens, Fanuc, Mitsubishi, and Allen Bradley control systems. Clients benefit from seamless transitions to advanced technologies, resulting in enhanced precision and operational efficiency, while minimizing downtime during machine conversions.

Tailored Services and Pan-India Support

We understand that every client's requirements are unique. Our customized retrofitting services are designed to address specific challenges faced by your machine or production process. We offer on-site support anywhere in India, ensuring timely service delivery and technical assistance as per your schedule.

FAQ's of Industrial CNC Machine Retro Fitment Services:

Q: How does the CNC machine retrofitting process work?

A: The retrofitting process begins with a detailed evaluation of your existing CNC machine. We then design an upgrade plan tailored to your operational goals, covering mechanical, electrical, and control systems. Our technicians perform all upgrades on-site, ensuring seamless integration and thorough testing before concluding the service.Q: What types of CNC machines are supported for retrofitment?

A: Our services cater to a wide range of industrial CNC machines, including turning centers, milling machines, VMCs, HMCs, and routers. We provide upgrade solutions compatible with popular control systems such as Siemens, Fanuc, Mitsubishi, and Allen Bradley.Q: What mechanical and electrical upgrades are included in your service?

A: We offer comprehensive mechanical upgrades like axes drive replacement and spindle enhancement. On the electrical side, our services include new wiring, panel upgradation, and servo motor replacement, all designed to optimize performance, durability, and safety.Q: When and where can the retrofitting services be availed?

A: Our retrofitting services are available throughout India, directly on your site. Depending on the project scope, service durations range from 1 to 12 months. We coordinate repairs offline to ensure minimal disruption to your daily operations.Q: What are the benefits of upgrading and converting CNC machines?

A: Retrofitting extends the operational life of your machines, boosts productivity, improves precision, and enhances safety. Upgraded machines also provide better compatibility with modern control systems, helping you stay competitive with current manufacturing standards.Q: Can services be customized according to specific client requirements?

A: Yes, each retrofitting solution is customized after assessing your unique operational needs, machine models, and production targets. We work closely with clients to ensure all upgrades align with their exact requirements.Q: Is there a warranty on your retro fitment services?

A: Absolutely. All upgrades and conversions are backed by a service warranty, giving you confidence in the reliability and performance of your newly retrofitted CNC machinery.CNC Retrofitting Lathe Machine Installation Service

50000 INR/Number

Minimum Order Quantity : 1 Number

About this product

We are rendering CNC Retrofitting Lathe Machine Installation Service to our patrons. Due to prompt completion, our offered service is extremely admired in the market. Our service meets on clients demand. Moreover, we render this service as per clients demand.

Upgrade Your Lathe Machines to Modern CNC Standards

Experience transformative improvements for your workshop by retrofitting your conventional or older CNC lathe machines. We utilize leading automation technology from renowned brands such as Fanuc, Siemens, and Mitsubishi, fully tailored to your requirements. With our ISO-certified procedures and skilled engineers, you gain reliability, higher productivity, and smoother operations during every installation.

Comprehensive Retrofitting Components and Process

We perform a complete replacement of outdated systems, integrating servo motors, drives, advanced controllers, new panels, wiring, and PLC modules. Our engineers ensure that your lathe machines fulfill all industrial automation and operational safety standards, leading to increased precision and reduced downtime. All work is meticulously documented for your convenience and regulatory needs.

Reliable Installation and Nationwide Coverage

Our installation service is provided offline-all over India-by highly trained CNC engineers. Depending on machine condition, installation typically takes between 2 to 5 days. We ensure compatibility with your power supply (3-phase, 415V, 50Hz), and provide after-sales support to keep your operation running optimally long after installation is complete.

FAQ's of CNC Retrofitting Lathe Machine Installation Service:

Q: How does the CNC retrofitting process work for lathe machines?

A: Our team systematically replaces the old systems with new CNC components, such as servo motors, drives, controllers, panels, wiring, and PLC modules. The entire process follows ISO-certified procedures for maximum safety and efficiency.Q: What types of CNC systems are supported in this retrofitting service?

A: We support CNC system retrofitting for Fanuc, Siemens, and Mitsubishi options, selected as per your operational needs and preferences.Q: When can I expect my retrofitted lathe machine to be operational?

A: Typically, the installation process takes between 2 to 5 days, depending on your machine's existing condition and specific requirements.Q: Where is this installation service available?

A: Our offline CNC retrofitting installation service is available throughout India, offering comprehensive coverage for industrial clients nationwide.Q: What are the main benefits of upgrading to a modern CNC system?

A: Upgrading to a modern CNC system improves your machine's precision, automation, reliability, and productivity, while also reducing downtime and maintenance overheads.Q: Is after-sales service provided once retrofitting is completed?

A: Yes, we offer dedicated after-sales support, including maintenance, troubleshooting, and technical assistance to ensure optimal machine performance.Q: What documentation is provided after installation?

A: You receive a complete installation report, operating manual, and test certificate for your records, all of which are essential for ongoing machine operation and compliance.CNC Machine Retrofitting Services

50000 INR/Number

Minimum Order Quantity : 1 Number

Main Domestic Market All India

About this product

Applications & Usage of CNC Machine Retrofitting Services

Our CNC Machine Retrofitting Services are extensively used for upgrading industrial CNC machines such as lathe, milling, turning, and grinding units. Ideal for manufacturing plants and engineering workshops, these services excel in enhancing operational efficiency and performance. Area of application includes automotive, aerospace, heavy machinery, and fabrication industries, where advanced automation and precision are critical. Utilized for productivity improvement and energy efficiency, they ensure flawless integration with modern technologies like robotics and Industry 4.0 systems.

Packaging, Samples, and Supply Details for Retrofitting Services

When providing CNC Machine Retrofitting Services to the export market, meticulous attention is given to safe packaging and secure dispatching of spare parts and electronic modules. Upon request, samples and demonstrations are available to prospective clients, showcasing our service quality and customization. We supply our solutions from major industrial hubs and conveniently offer FOB (Free On Board) at prominent Indian ports. Timely supply and dispatch ensure uninterrupted installation and maintenance support for clients across regions.

FAQ's of CNC Machine Retrofitting Services:

Q: How long does the CNC machine retrofitting process typically take?

A: The installation time for CNC machine retrofitting averages between 2-4 weeks, though the exact duration depends on the complexity of the project and the specific requirements of the machine.Q: What types of CNC machines can be retrofitted with your services?

A: Our retrofitting services cover a wide range of CNC machines including lathe, milling, turning, and grinding machines, ensuring compatibility with all major CNC brands for enhanced flexibility.Q: Where are your retrofitting and support services available?

A: We offer onsite CNC machine retrofitting and technical support services pan India, catering to manufacturers and industries in all regions of the country.Q: What benefits can I expect from upgrading my CNC machine through retrofitting?

A: Retrofitting your CNC machine can deliver outstanding productivity enhancements of up to 40%, improved energy efficiency, seamless integration with robotics and Industry 4.0, and reliable long-term performance with genuine spare parts and post-installation support.Q: How does your post-installation support work for clients?

A: We provide comprehensive post-installation support, which includes round-the-clock technical assistance, operator and maintenance training, periodic inspection, and maintenance services for sustained performance.Explore Additional Categories

Contact Us

Our Products

Our Products